Undercarriages

Precision undercarriages from Komatsu

The undercarriages of crawlwer or track vehicles represent a complex mechanism consisting of many independent components, which must function precisely even under extreme conditions. Undercarriages from Komatsu possess long service life and have been designed to cope with very high workloads. But of course, they are still susceptible to a certain degree of wear.

KUC – Komatsu Undercarriage Inspection Service Programme

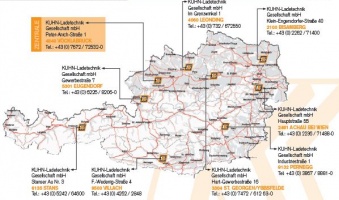

To avoid problems related to undercarriages, Kuhn has established a preventative programme. This was introduced under the name Komatsu Undercarriage Inspection Service Programme. This enables Kuhn service technicians to calculate the level of wear on undercarriage components through simple measurements together with a specially developed computer programme from Komatsu. This allows the remaining lifetime of undercarriage components to be estimated. In addition, the Komatsu Undercarriage Inspection Service Programme provides exact information about necessary maintenance procedures, and therefore also offers a detailed overview of future costs.

Uncomplicated and fast inspection

The Komatsu Undercarriage Inspection Service Programme is an effective and fast inspection system, which makes it possible to plan ahead for repairs and replacements. This minimises down-time and procurement time. The programme works in the following way: Kuhn specialists record the data from the building machine and measure the undercarriage. The data is then fed into the analysis programme, where the percentage of wear is calculated automatically. Kuhn specialists then use the results to make recommendations regarding necessary repairs and maintenance steps.